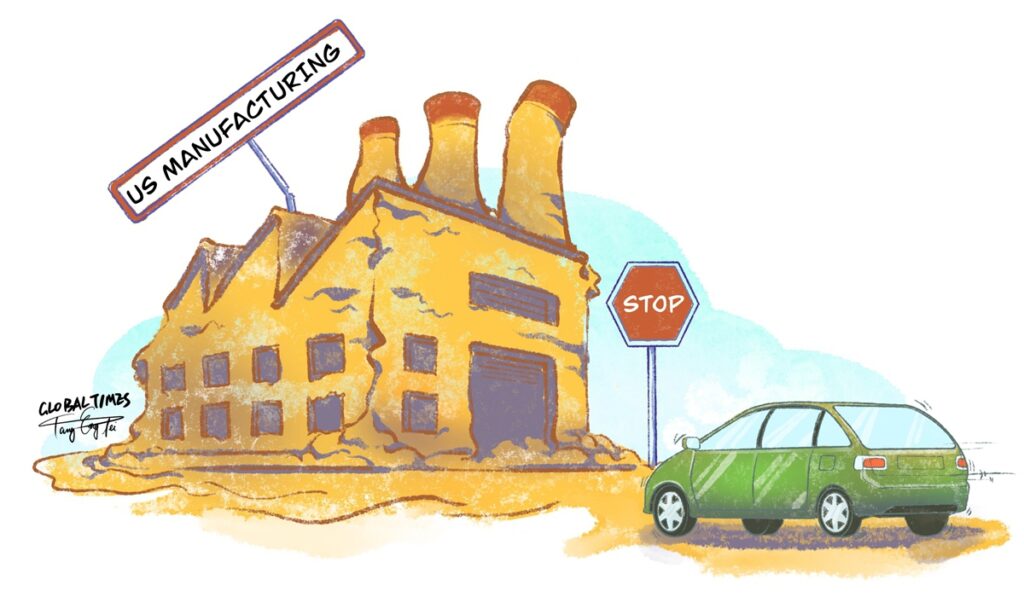

Instead of truly driving reindustrialization in the US, policies aimed at boosting American manufacturing seem to only result in higher costs and more debt, underscoring the irrationality of US politicians targeting Chinese manufacturing. The latest example is the “All-American Flag Act,” which was signed into law by President Joe Biden on Tuesday.

The proposal requires the federal government to purchase flags that are produced entirely with American-made materials and made in the US, the Associated Press reported.

The US imports millions of American flags annually, mostly from China. The value of US flag imports in 2015 was well over $4 million, according to federal data. In 2017, the US imported some 10 million American flags, and 99.5 percent of them came from China, supporters of the proposal said.

These flag imports make up only a minuscule part of the economic relationship between the US and China, so the move by US politicians to make domestic flag production compulsory for purchases by the federal government is ostensibly intended to support domestic manufacturing in the hope of keeping industry and jobs in the US.

But in reality, this exposes the hysteria about boosting American manufacturing and cracking down on Chinese manufacturing.

The production of a flag may appear simple, but it actually involves a complex industrial chain. In China, some regions specialize in the production of flags for countries worldwide, and economies of scale have helped to bring down production costs. This is how $4 million can meet the annual demand for American flags. If the US were to produce all the flags needed by the government, how many American flag factories could $4 million sustain?

Indeed, it is not hard to imagine that without economies of scale and a well-established industrial chain, the production cost of a flag manufactured in the US would likely be significantly higher than in China. This would mean increased expenses for government procurement, adding to the strain of soaring budget deficits and potentially sparking concerns and criticism regarding government expenditure.

Even if the US government were willing to pay the higher costs, there is no guarantee that there would be enough domestic production capacity to meet its flag needs.

Flag Act is just one aspect of US efforts to crack down on Chinese manufacturing. Washington has been pursuing reindustrialization in recent years, only to see a growing list of Chinese products being targeted by the US, with no significant improvement in American manufacturing and an accelerated increase in federal government debt. This is due to the growing irrationality of the US toward “decoupling” from China, leading to excessive political intervention in areas where market allocation should prevail, ultimately raising the costs of domestic production and operation.

High costs aren’t the only obstacle to the reindustrialization of the US. The issue of labor shortage also severely restricts the “made in America” ambition. Take TSMC’s factory in the state of Arizona as an example. In 2023, TSMC said production at its first fab would be delayed from 2024 to 2025, due to a shortage of specialist workers. To combat the labor constraints, TSMC planned to start importing workers from the Taiwan island, which prompted an outcry from the local construction union in Arizona.

Now, approximately 2,200 employees work at TSMC’s Arizona plant, with about half of them being deployed from the island of Taiwan.

Clearly, without addressing the critical talent shortage in the manufacturing industry, the reliance on symbolic measures such as the Flag Act will not provide any substantial help for the reindustrialization of the US.

The comparative advantage of the US actually lies in high-tech products, but now, for its own distorted competitive goals, it repeatedly goes against market rules and insists on protectionism in areas where it doesn’t have an advantage. Eventually, economic laws mean it will fail.

GT