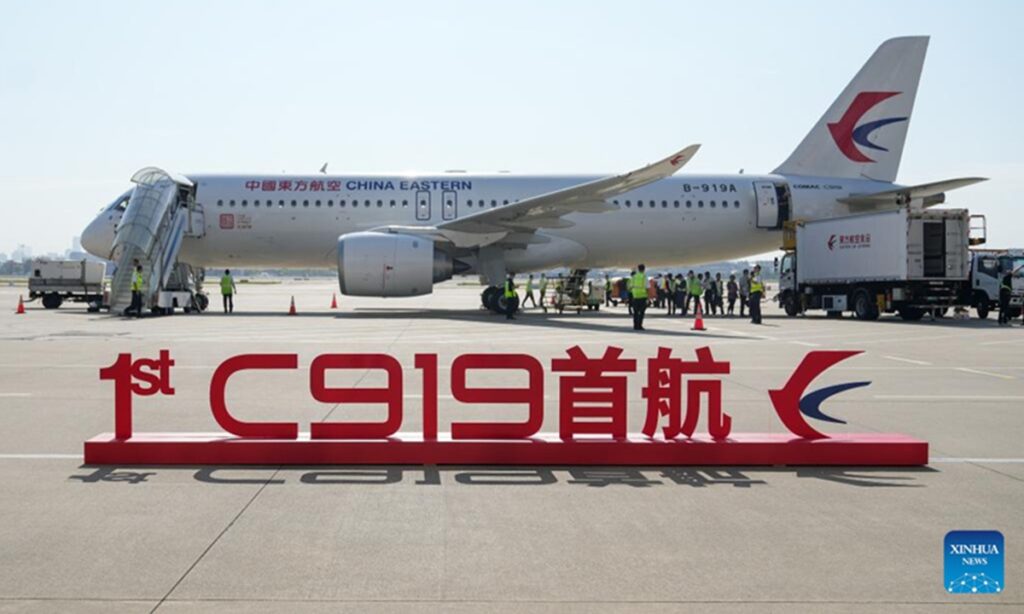

The maiden commercial flight by China’s first domestically-manufactured large passenger aircraft C919 on Sunday marks its official entry into the civil aviation market, which represents not only a milestone for China’s high-end manufacturing, but also ushers in a new era for the cooperation between Chinese manufacturers and foreign companies.

For years, questions about the C919 have focused on how many components of the aircraft are imported from abroad. It is true that there is a long list of foreign suppliers for the C919, which involves Honeywell’s electricity system and landing gear, GE’s flight recorder, CFM Leap’s engine, Parker Aerospace’s flight control system and fuel system, Rockwell Collins’ weather radar and simulate system, and Michelin’s tire. That is also why some people have been questioning whether the C919 can be called a domestically-manufactured aircraft when it relies on imports for about 40 percent of its components.

Yet, anyone with basic knowledge about aircraft manufacturing will understand that it is not simply the assembly of parts, but a high-tech process that involves highly sophisticated designs. The design, integration and manufacturing of large passenger aircraft are the ultimate tests of a nation’s aviation manufacturing capabilities. This involves various areas such as new materials, electronic information, mechanical manufacturing, automatic control, computer technology, and high-end equipment, among others.

With the C919, the Commercial Aircraft Corporation of China is the only company, in addition to Boeing and Airbus, that has its own independent aircraft designs and the capability to integrate various parts and systems into the aircraft. Many countries have tried to make their own civil aircraft, but most have failed. For instance, although Japanese companies supply many parts to Boeing’s aircraft, Japan has not yet produced its own passenger aircraft after more than one decade of efforts. After a project, which was launched in 2008 under the name of Mitsubishi Regional Jet, suffered repeated setbacks and missed its 2013 rollout, Mitsubishi Heavy Industries has said it will cancel the public-private SpaceJet project, marking the end of Japan’s plans to build its first homegrown passenger jet.

China’s rapidly developing large passenger aircraft manufacturing system is of great significance to the growth of the civil aviation industry and the entire Chinese manufacturing industry. Notably, foreign companies are now participating in China’s large passenger aircraft manufacturing system by supplying customized components, marking a significant shift from the past when the Chinese manufacturing sector primarily catered to the needs of foreign producers.

China needs cooperation with the rest of the world, while foreign companies need market, which is one of China’s advantages. As China’s manufacturing strength rises, there will be an increasing need for foreign companies to serve customized local demand, rather than simply providing products. Only those who are integrated into the Chinese manufacturing system and can contribute to China’s manufacturing upgrading can achieve the maximization of interests. In the case of the C919, the parts supplied by foreign companies are all customized based on the design requirements of the C919.

In addition, there may be concerns that imported components for China’s aircraft manufacturing could be cut off by certain countries, similar to what has occurred in the semiconductor supply chains. If some in the West aim to disrupt a mutually beneficial cooperation and partnership between industries, it will only limit their businesses’ opportunities to enter the Chinese system and generate profits.

But just as the chip ban won’t stop China from conducting independent research and innovation to break technological containment, any cutoff won’t prevent China from developing its own high-end manufacturing system and promoting self-made products to the world, such as the high-speed rail.

(Global Times)